Multi-column Water Distiller and WFI Storage

- Home

- Multi-column Water Distiller and WFI Storage

Multi-column Water Distiller and WFI Storage

WEMAC’s LDS Series Multi–column Water Distiller is a kind of equipment to produce water for injection by using purified water as feed water and heating with industrial steam. The water for injection produced by LDS Multi–column Water Distiller meets the specification requirements of Chinese Pharmacopoeia (CP2020), U.S. Pharmacopoeia (USP43) and European Pharmacopoeia (EP10) for water for injection.

Working Principle

Qualified feed water is pressurized by multi–stage pump into the Condenser, and then sequentially into each Preheater (feed water in the Condenser is heated by the secondary steam, distilled water, and then into each Preheater after the condensed water is heated by the secondary steam, and in the first Preheater is heated by the condensed water of the industrial steam), and then into the first Evaporator through the feed water distributor is sprayed on the inner wall of the heating tube, so that the feed water in the wall of the tube becomes a film flow, and is heated by the industrial steam.

Heating vaporization produces entrained water droplets of the secondary steam from the lowe end of the evaporation chamber into the vapor separation device, which are separated from the pure steam into the next Evaporator as a heating steam.

Non–evaporated feed water enters the next Evaporator to repeat the above process.

The pure steam produced by the final Evaporator enters the Condenser with the condensed water from the condensed water in addition to the first Evaporator of the convergence of cooling, by excluding non condensable gases (depending on the model, the Evaporator can also be equipped with such non condensable gas discharge devices) to become the water for injection.

The outlet is usually tested online for conductivity, and qualified distilled water is exported as water for injection, while unqualified distilled water will be discharged.

Product Features

- Structure: External Preheater, Condenser and the first Evaporator are all double tube plate design, using the inner tube plate expansion outside welding process, to avoid cross contamination.

- Separation device: Three–stage separation with falling film evaporation, gravity separation and spiral flow.

- Material: SS316L is used in all parts in contact with raw water, water for injection and secondary pure steam.

- Thermal insulation: Evaporator, preheater, condenser are insulated with aluminum silicate needled blanket, which has good extensibility, light weight, excellent thermal insulation and strong stability.

- Surface treatment: Electrochemical polishing of internal and external surfaces effectively ensures the surface finish of stainless steel.

- Energy saving and consumption reduction: Multi–column Water Distiller has obvious energy saving effect because the secondary steam is utilized step by step in each column, so the utilization rate of industrial steam is very high. With the increase of the number of Evaporator columns, this energy saving effect is more obvious. At the same time, the amount of cooling water is also greatly reduced with the increase in the number of columns. Our company produces five–column Water Distiller using a small amount of cooling water, six–column Water Distiller without cooling water.

- Pipes: As far as possible using stainless steel pipe directly stretching and bending, to avoid welding. Pipes and fittings weldments using argon gas protection automatic welding (single sided welding and double–sided molding process), to ensure the quality of welding, post–weld electrochemical polishing.

- Provide endoscopic inspection photos, welded joints diagram, pressure test and pickling passivation report and system design documents and other verification information.

- Control system: Adopts HMI+PLC full–automatic control with easy operation interface. Various communication modes are available. Control system authority level: at least three levels of authority can be set.

- Monitoring: Online monitoring of conductivity, temperature and flow and other parameters. The recorder can choose paperless recorder or paper recorder to record and print the key parameters.

- Compliance: The control system can be equipped with electronic signatures, electronic records, so that the system control has an audit trail function, and to meet the requirements of GAMP 5 and 21 CFR PART 11.

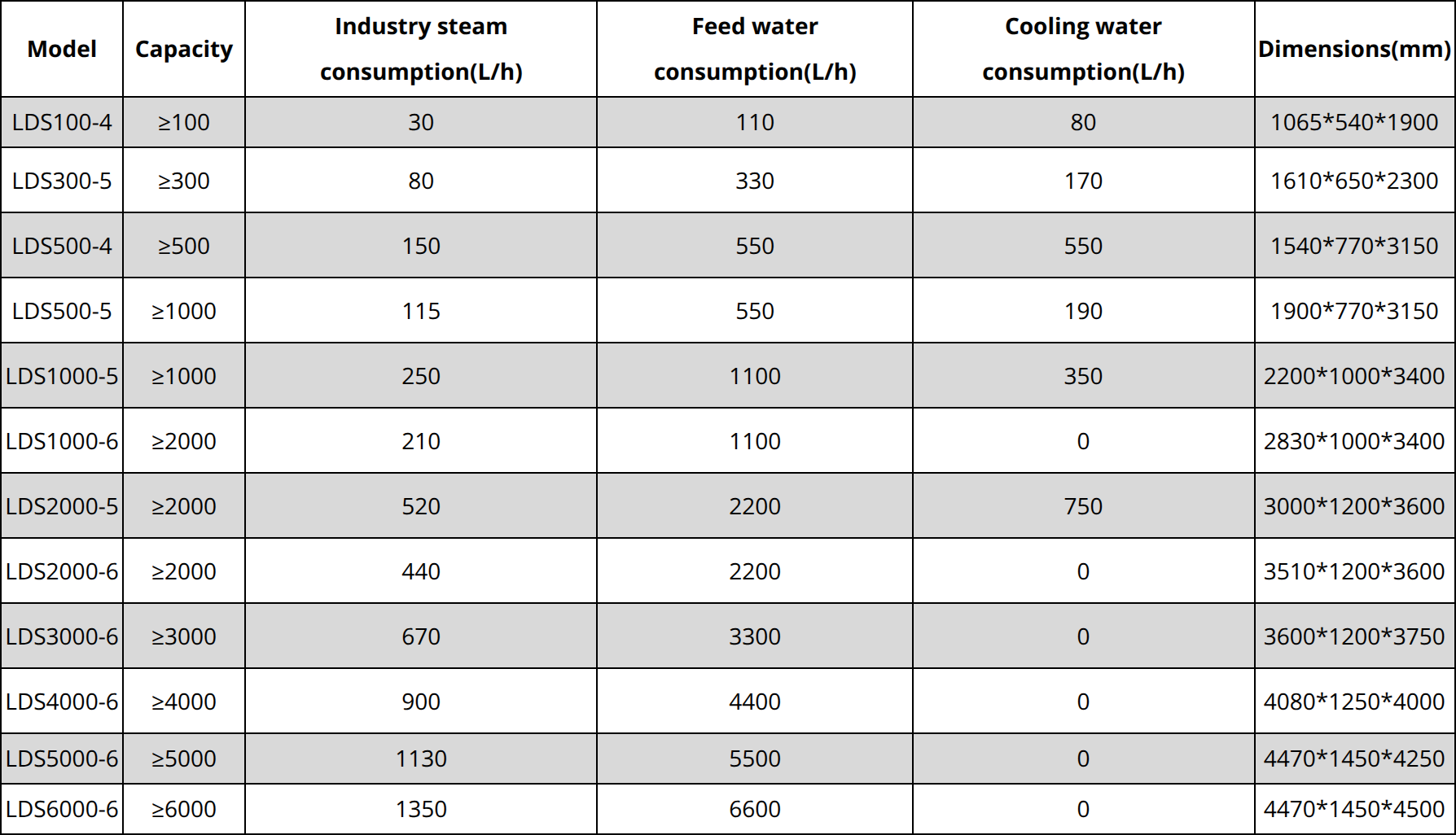

Parameter Table