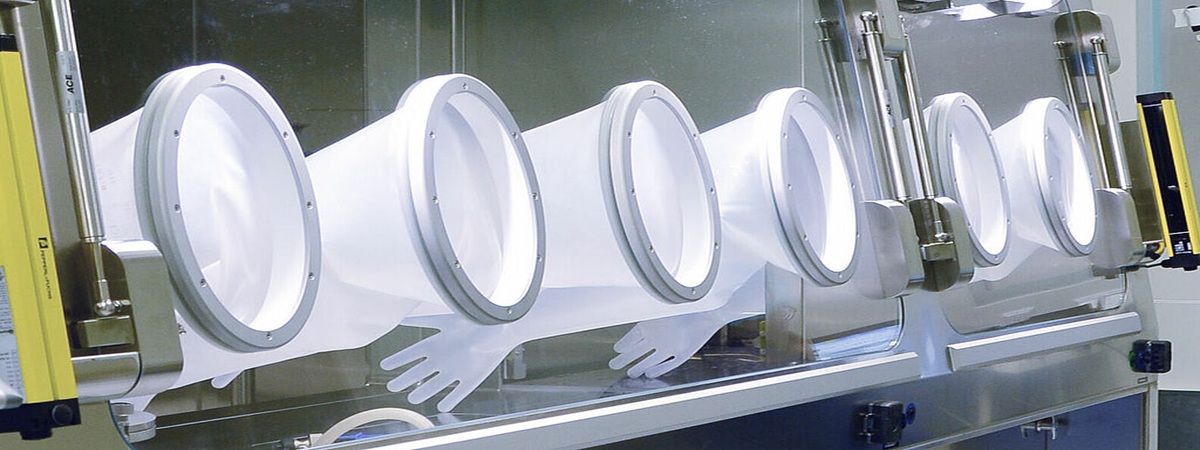

Containment Isolator

- Home

- Containment Isolator

Containment Isolator

Containment isolator is designed for protecting the operators when weighing, dispensing, drying, pressing, filling highly potent and toxic products.

Product Features

- OEB 4 or OEB 5: Provides high-level operator exposure protection for potent compound handling.

- H14 Cylinder HEPA Filters (PUSH-PUSH): Ensures efficient air filtration and easy filter replacement without contamination.

- Continuous Liner Bag System: Enables safe and contained material transfer to prevent product or operator exposure.

- Control System: Siemens PLC control with HMI for reliable, user-friendly operation.

- Automation: Fully automatic control and operation, reducing manual intervention.

- Real-time Monitoring: Continuously monitors differential pressure, humidity, and temperature for consistent performance.

- Data Management: Critical process parameters can be stored and printed for validation and traceability.

- Regulatory Compliance: Fully complies with 21 CFR Part 11 requirements for electronic records and signatures.

Technical Parameters

| Power supply: 220V 50Hz |

| Chamber Material: SUS316L |

| Airflow model: Turbulent |

| Chamber Pressure: -80Pa to 50Pa adjustable |

| Air changes rate: More than 24 times/hour |

| Noise: <65dB(A) during negative pressure holding |

| Leak tightness: Meet ISO10648-2 requirements |

Options

| Laminar flow with Bag-in-Bag-out H14 HEPA filters | ||||

| Explosion-proof | ||||

| The vibration-free platform for precision weighing | ||||

| WiFi-controlled glove integrity tester (GIT-WLAN) | ||||

| Wooden Mock-Up |

Services

Complete validation protocols to comply with FDA, EMA, GMP, 21CFR Part 11

FAT, SAT, Training